Circular saws and plunge saws are two popular choices among woodworking enthusiasts and professionals. Both saw types are used for cutting, they have a similar construction, and they utilize circular blades, but each of them has its own set of advantages and ideal use cases.

In this article, we’ll delve into the differences between circular saws and plunge saws, exploring their features, benefits, and best applications. By the end, you’ll be better equipped to decide which saw suits your woodworking needs.

Similarities

Circular and plunge saws share common elements and features, which include:

- Circular Blade: Both saws use circular blades with sharp teeth for cutting various materials, such as wood, metal, plastic, stone or even concrete. The circular blade is available in different sizes and tooth configurations, allowing it to cut through various materials with ease.

- Motor: Circular saws and plunge saws are equipped with electric motors that power the rotation of the circular blade, providing cutting force.

- Depth Adjustment: Both saws offer depth adjustment features, allowing users to control the cutting depth based on the thickness of the material being cut.

- Bevel Adjustment: Most circular saws and all plunge saws come with bevel adjustment capabilities, enabling users to make angled cuts.

- Portability: Both types of saws are available in corded and cordless versions, providing portability and ease of use on job sites or in small workshops.

- Safety Features: Circular saws and plunge saws are designed with safety features, such as blade guards, to protect users from potential accidents during operation.

- Cutting Capacity: Both saws are capable of making fast straight cuts through various materials, making them suitable for crosscuts and ripping.

- Versatility: Circular saws and plunge saws are versatile tools suitable for a wide range of woodworking and construction tasks.

- Ergonomic Handle: Both saws feature an ergonomic handle that ensures a comfortable grip during use.

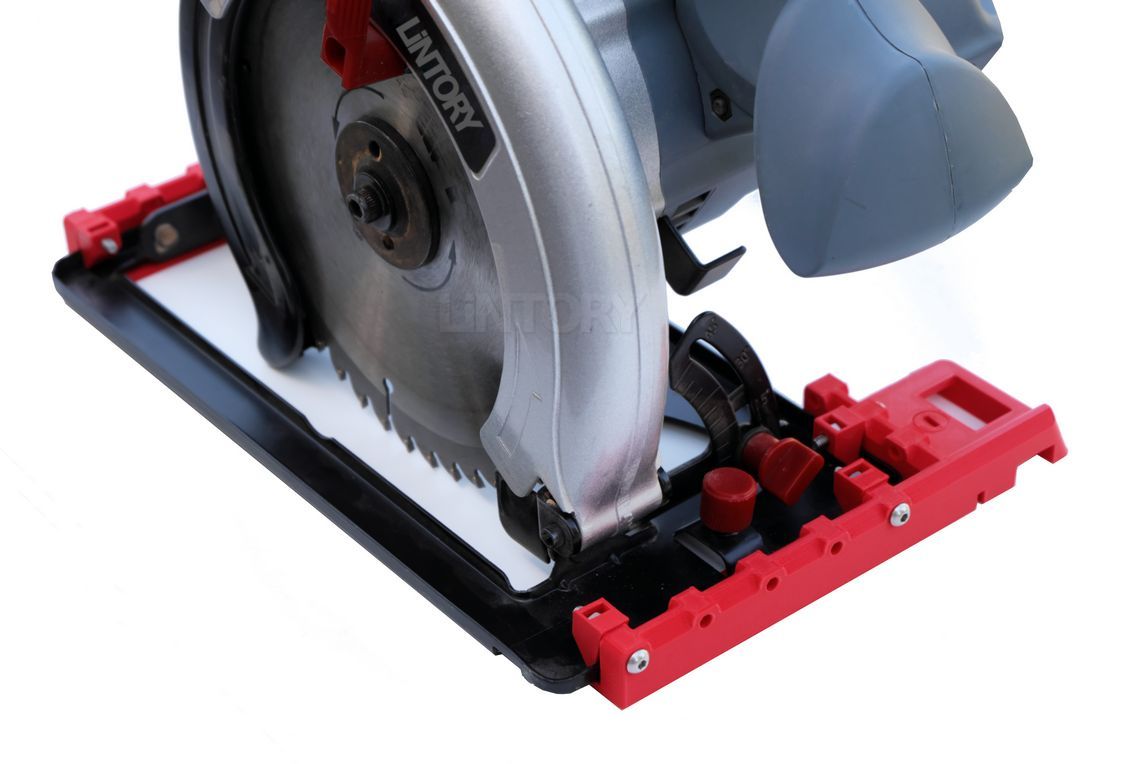

Circular Saw:

The circular saw is a versatile power tool used in various woodworking projects. It is much more suitable for straight cuts than jigsaw or band saw, but since very few models are compatible with guide rails, achieving a perfectly straight line can still be a challenge. Some saw models can be adapted to guide rails using special accessories, which have to be bought separately.

Circular saws come in many, many sizes, which, depending on your needs, allows choosing a model that can either cut very thick elements or can be operated in tight places.

Here are some key features and benefits of circular saws:

- Straight Cuts: Circular saws, in contrast to jig saws, are good for making straight cuts in wood, which makes them ideal for tasks like crosscuts and ripping lumber.

- Lightweight: They are lighter than plunge saws of similar blade size, which is invaluable in everyday use on construction sites.

- Blade size range: Size range of circular saws is much larger. There are big models that allow you to cut thick logs of wood as well as small handy ones that can be operated even with one hand.

- Budget-Friendly: Compared to plunge saws, circular saws are generally more budget-friendly, making them a popular choice for DIYers and hobbyists.

As you might expect, circular saws have some disadvantages compared to plunge saws:

- Poor dust extraction

- No plunge capability

- Usually not compatible with guide rails (sometimes rail adapters may help)

- Lack of precision depth and bevel controls

Plunge Saw:

The plunge saw, also known as a track saw, shares similarities with the circular saw but offers additional elements tailored to precision cutting. In contrast to regular circular saw, all plunge saws are compatible with some guide rail system. The guide rail serves as a track that guides the saw during the cutting process, ensuring perfectly straight and accurate cuts.

Plunge saws excel at plunge cuts, where the blade is lowered directly into the workpiece at any point, eliminating the need for starting from an edge. This feature is particularly beneficial when working with large sheet materials, as it minimizes the risk of splintering. Plunge saws also come equipped with precise depth and bevel adjustments, offering versatility in different applications. The retractable blade guard adds an extra layer of safety, and some models feature dust extraction systems to keep the workspace clean and visible during cutting.

They are gaining popularity among woodworking professionals due to their outstanding features:

- Guided Accuracy: Plunge saws are equipped with a track or guide rail system that provides a straight cutting path. This ensures precise and straight cuts, even when starting in the middle of a workpiece (plunge cuts).

- Splinter-Free Cuts: Thanks to splinter guard, guide rail also helps reduce splintering on the top surface of the workpiece, resulting in cleaner and smoother cuts.

- Precise control: Setting cutting depth and bevel angle is much easier thanks to the precise scales.

- Safety: Plunge saws feature a retractable blade guard, which covers the blade when not in use, enhancing safety during operation.

- Dust extraction: All plunge saws have fully covered blade, and they can be connected to dust extractor

- Plunge option: Cutting can be started anywhere on a material

However, I must point out that changing the blade on a plunge saw can take a little longer because of cover. There are also heavier and more expensive than circular saws.

Circular Saw vs. Plunge Saw: Best Applications

a. Circular Saw:

Ideal for general woodworking tasks, such as crosscuts and ripping.

Suitable for DIYers and hobbyists on a budget.

Offers portability for on-site work or small projects.

b. Plunge Saw:

Best for precise and splinter-free cuts, especially in sheet materials.

Perfect for cabinet making and furniture projects.

Preferred by carpenters for its accuracy and efficiency.

Conclusion:

In conclusion, both circular saws and plunge saws have their unique advantages and applications in the woodworking world. The choice between the two depends on your specific needs, budget, and the level of precision required for your projects. If you are a DIY enthusiast looking for versatility and affordability, a circular saw might be the right fit. However, if you are a woodworking professional seeking precise and guided cuts, a plunge saw with its track system might be the ideal option.

Ultimately, whichever saw you choose, always prioritize safety and use proper safety equipment when operating power tools. Happy woodworking!

Popular circular saw accessories:

Universal circular saw guide rail adapter

Circular saw to guide rail adapter.